It’s important for companies in the manufacturing industry to understand which mode they fall into so their needs can be met with an appropriate ERP and ERP partner. Whether it is primarily order-taking or collaborative production and sales processes, or inventory management possibilities. The mode of manufacturing used by a company determine the best course of action when making ERP implementation choices.

Sabre is an expert business central manufacturing partner. Through our experiences we have seen many failed manufacturing ERP implementations. Those that result from a misunderstanding of the needs specific to the company’s mode of manufacturing occur more than from any other reason.

The term “mode of manufacturing” is used interchangeably with “manufacturing methods” or “types of manufacturing processes.” The term commonly and refers to how manufacturers produce a product and how they manage both the orders and inventory of products.

The mode of manufacturing used by a company is often a little difficult to pinpoint exactly, as many of these definitions have shades of grey between them.

This article will give you an overview of the most common modes of manufacturing and help clarify those areas of confusion for you.

If you enjoy this article and would like to talk to Sabre Limited’s president Robert Jolliffe to chat about these concepts, you can book a one-on-one 30-minute call with him at https://calendly.com/robert-jolliffe

“Modes of Manufacturing Drive ERP Implementation Choices”

Manufacturing processes in the United States can generally be classified into three categories: mass production, job production and batch production. As mentioned above, however, there are also subtle variations depending on the nature of the manufacturer.

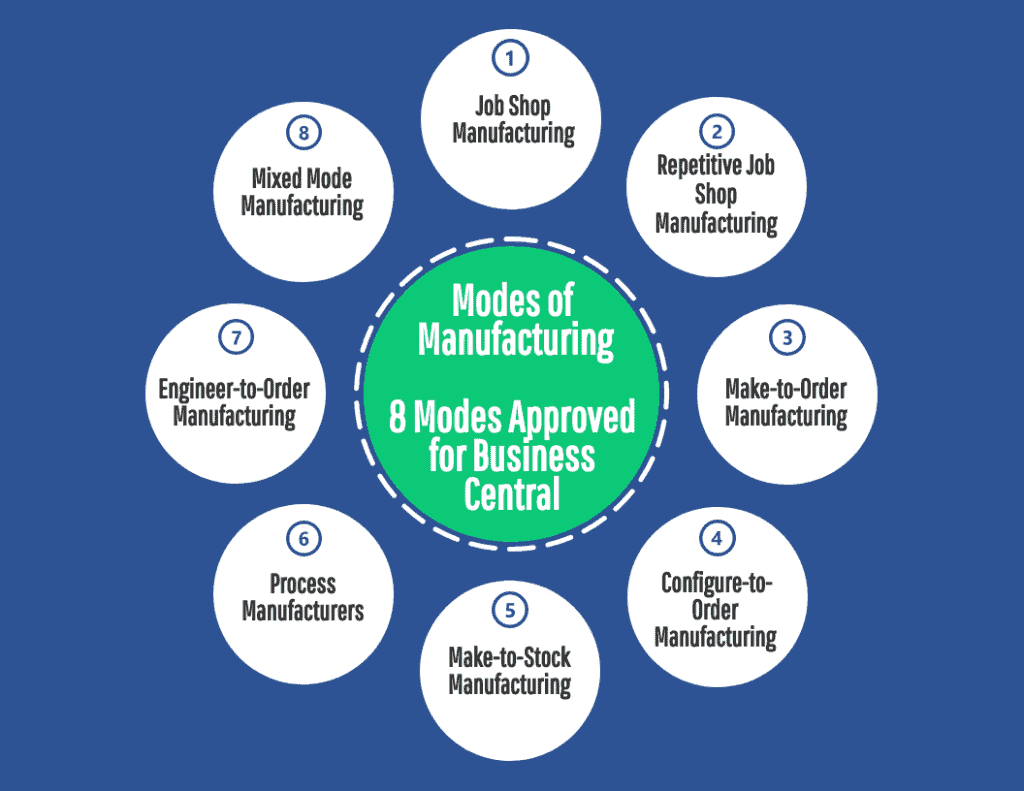

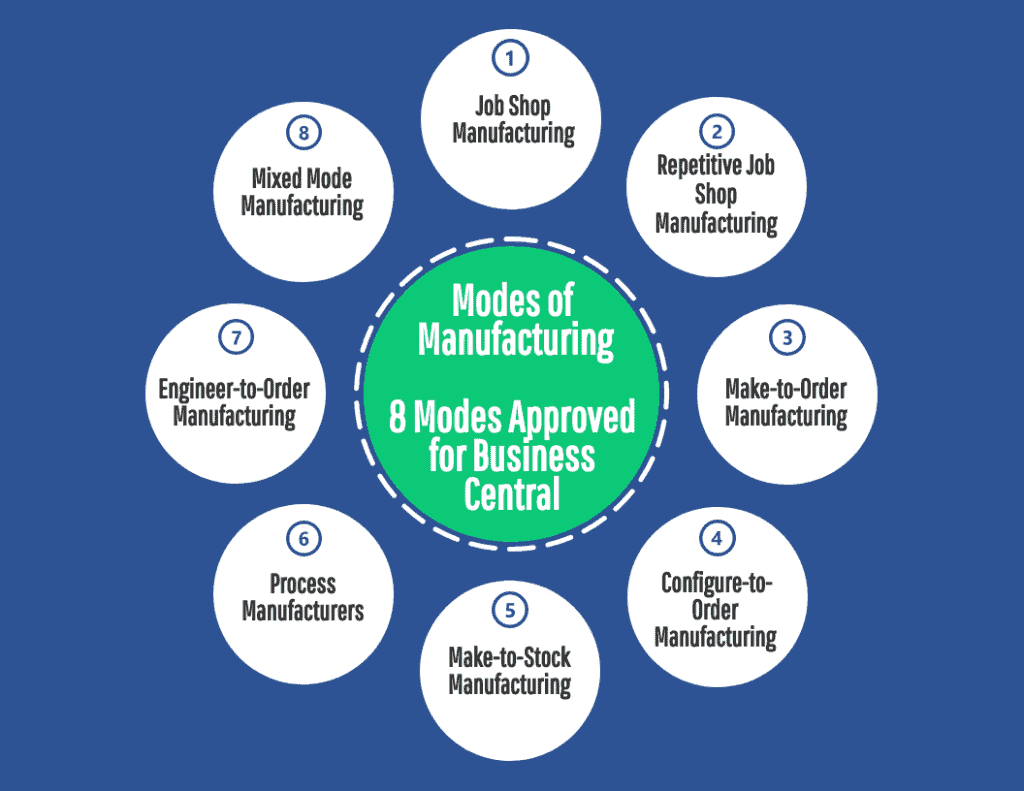

As a leading business central manufacturing partner in North America, Sabre Limited has been providing businesses in the manufacturing industry with the tools they need to be successful. While gathering our years of experience working with manufacturing companies, we have identified eight distinct variations in the three main modes of manufacturing. There are some things common to all the modes of manufacturing, such as quality control, but there are many differences in production technique.

Below we go into more detail about each of the eight modes of manufacturing.

1. Job Shop Manufacturing

The classic Job Shop is a small company in the manufacturing industry with a collection of equipment they “outsource” to their customers. Job Shop manufacturers are usually subcontractors who bid on jobs from larger producers who need one-time or short runs made for their project needs.

Job shops usually only buy materials for the specific job when they are doing that job, they don’t keep raw materials in stock. They focus on employee costs and managing quotations and estimates. This is the most common type of manufacturing.

What’s important: Job (actual) Costing, Purchasing to Jobs, Labour Collection, Estimating, Quotation Tracking.

What’s not important: MRP, MPS, Inventory Control, Price Lists, Production (standard) Costing, Sales Forecasts, Usage Forecasts.

Business Central Fit: Excellent

2. Repetitive Job Shop Manufacturing

Sometimes a job shop will specialize in a certain type of production. These job shops are called “repetitive job shops.” These shops will buy raw materials to keep in stock because they are committed to delivering parts over a given period of time. Often, material delivered to these shops is owned by the customer, and the customer requires tracking and reporting on this inventory. Out of all the types of manufacturing, repetitive job shops are probably the second most common. They do not build to stock, nor to forecast. They build only based on the firm orders their customers have given them.

What’s important: Job (actual) Costing, Purchasing to Jobs, Purchasing to Stock, Labour Collection, Estimating, Quotation Tracking, Inventory Control.

What’s not important: MRP, MPS, Pricebook, Production (standard) Costing, Sales Forecasts, Usage Forecasts.

Business Central Fit: Excellent

3. Make-to-Order Manufacturing

The make-to-order manufacturer has created a line of products for sale. They do not create products based on a customer’s designs or engineering specifications. They have their own engineering staff, manage drawings and keep raw materials in stock. This type of manufacturer typically has a price book, which is a list of prices they charge different customers for the same product.

Make-to-order manufacturing is a type of manufacturing process in which products are only produced after an order has been placed. This contrasts with other modes of manufacturing, such as mass production or assembly line production. Make-to-order can be contrasted with make-to-stock, in which products are produced in advance to keep in stock in anticipation of consumer demand.

Among the modes of manufacturing, this is very common.

What’s important: Production (standard) Costing, MPS, MRP, CRM, Inventory Control, WIP control, Usage Forecasts.

What’s not important: Job (actual) Costing, Estimating, Quotations (except as part of CRM), Sales Forecasts.

Business Central Fit: Excellent

4. Configure-to-Order Manufacturing

Configure-to-order manufacturing is a mixed mode manufacturing process where products are sold from a catalogue, but customers are allowed to “modify” the product within parameters. Make-to-configure manufacturing is therefore ideal for situations where customizability is important. This type of manufacturing is popular among companies like DELL computers and FORD car company.

Configure-to-order manufacturing is often used for products that are highly customized or made in small quantities. As a result, it can be more costly and time-consuming than other modes of manufacturing.

The advantage of this system is that it allows for customization and personalization of products, which can be appealing to customers. The downside is that it can lead to longer lead times and higher costs, as each product is effectively made to order. Nevertheless, configure-to-order systems can be an effective way to manufacture products that are tailored to customer needs.

What’s important: Product Configurator for Business Central, Job (actual) costing, MPS, MRP, CRM, Inventory Control, WIP control, Usage Forecasts.

What’s not important: Estimating, Quotations (except as part of CRM), Sales Forecasts

Business Central Fit: Needs Product Configurator Add-on – Otherwise Excellent

5. Make-to-Stock Manufacturing

The make-to-stock manufacturer is like the Make to Order manufacturer, except they have a shorter lead time for delivering their product than they have for manufacturing it. The market generally drives this and forces them to keep an inventory of their finished goods to sell. Some make-to-stock manufacturers can cope with fluctuations within safety stock. For others, a sales forecast is a critical requirement, as they must have some sense of the sales volume expected to know what and how much to manufacture.

Make-to-stock manufacturers rely on available finished goods inventory to sell their products. These types of manufacturers are the most common. Companies like General Motors and General Electric are examples of this type of manufacturer. They often use assembly line style production organization.

While this approach can be more efficient in terms of cost and time, it may not always result in products that perfectly meet the customer’s needs.

What’s important: Production (standard) costing, MPS, MRP, CRM, Inventory Control, WIP control, Sales Forecasts

What’s not important: Job (actual) Costing, Estimating, Quotations (except as part of CRM), Usage Forecasts.

Business Central Fit: Excellent

6. Process Manufacturers

Now we are on to the “oddest” of the modes of manufacturing. Process manufacturing is primarily defined by two things. First, the product being manufactured must be contained in a vessel of some kind because it is a powder, liquid, or pellets. Second, the product is made of a recipe which when combined cannot be disassembled.

There are two main types of process manufacturing: batch and continuous. In batch manufacturing, the product is made in batches, or groups of products. In continuous manufacturing, the product is made all at once.

This type of manufacturing is used in a variety of industries, from food production and beverages (everything from peanut butter to Coca-Cola) to pharmaceuticals and cosmetics. Process manufacturing often involves delicate and precise recipes.

Formulas and recipes are used in place of bills of material and routings. They typically “cook” or otherwise chemically alter their product. Smaller process manufacturers, often called pilot plants, function more like job shops where small quantities of special products are produced in a non-repetitive environment.

What’s important: A process manufacturing-specific solution for their Business Central implementation.

What’s not important: Discreet manufacturing features.

Business Central Fit: Poor out of the box. Needs Significant Addon.

7. Engineer-to-Order Manufacturing

Of all the modes of manufacturing discussed in this post, Sabre has particular expertise with ETO manufacturing. The engineer to order company may look like a job shop but it is vastly different.

Engineer-to-order companies are often engineering-heavy and production light, and the ratio of engineers to production staff is a good sign to look for when determining if a business is engineer-to-order. Engineer-to-order companies have more engineers than production staff. It is also normal to have quantities produced of maximum one or two units.

Engineer to order companies design machines to produce, rework, or test products and assist with product development as specified by their customers. They may have a job shop like production area with a variety of machines or they may only conduct final assembly. They often purchase most of their parts from subcontractors and tracking purchases against a job is critical to them. Actual job costing, WIP, and revenue recognition are requirements as their jobs will often take months or even years to complete.

Some engineer to order companies also install, service, and manage their products. They occasionally look like the Make to Order or Configure to Order modes of manufacturing if the products they engineer appear very similar.

One key “tell” of an engineer-to-order company is they call their sales “projects” or “jobs”. They are doing a lot of product development.

What’s important: Project Costing (unique accounting requirements), Purchasing to Jobs, Labour Collection, Estimating, Quotation Tracking.

What’s not important: MRP, MPS, Inventory Control, Price Lists, Production (standard) Costing, Sales Forecasts, Usage Forecasts.

Business Central Fit: Medium out of the box. Excellent with Sabre ETO Addon.

8. Mixed Mode Manufacturing

Mixed mode manufacturing is an extremely common situation, but basically describes a company that exhibits more than one of the modes of manufacturing. Microsoft documents mixed mode here. It can be very tricky implementing ERP at a mixed-mode manufacturer, especially if the implementation team perceives the company as falling primarily in a specific mode rather than recognizing they are mixed mode.

Mixed mode manufacturing requires the most complex Microsoft Dynamics Business Central implementation because it involves accommodating each mode and often the “process” design involves multiple ways to do the same “activity.”

In a Job Shop/Make-to-Order manufacturer, Material Requirements Planning (MRP) and standard costing might be required for common parts on the make-to-order product line, while buy-for-job type costing is required for the job shop portion of the business.

Identifying where mixed modes of manufacturing exist, and training users to handle the requirements is the most complex part of Business Central implementation in manufacturing.

Business Central Fit: Good

Conclusion: Which Mode Does Your Business Practice?

We hope this article clarified for you the different modes of manufacturing and how they correspond to Dynamics 365 Business Central.

The eight modes of manufacturing we’ve looked at today are all different in terms of the way they produce things, the type of customer they serve, and how they order and stock raw materials.

It’s important to understand which mode your business falls into so that you can make the most efficient use of resources and better serve your customers. Have you found that your company operates in a particular mode? Or do you think it is a mixed-mode manufacturing business? Did you learn something new from this article that you can apply to your own business?

If you have any questions about which features and functions your business needs, please reach out to us for assistance.

Need Some Help?

Sabre’s unique approach to training and implementing is recognized widely as the leading Business Central Manufacturing Partner in North America. We’ve helped several companies start their own programs, adding value for each of our client’s needs with customized services that fit seamlessly into any environment. Reach out today if you’re interested!

If you need help with a Dynamics 365 Manufacturing systems choice, give us a call at: (519) 585-7524 or contact our team, we’re excited to talk with you soon!